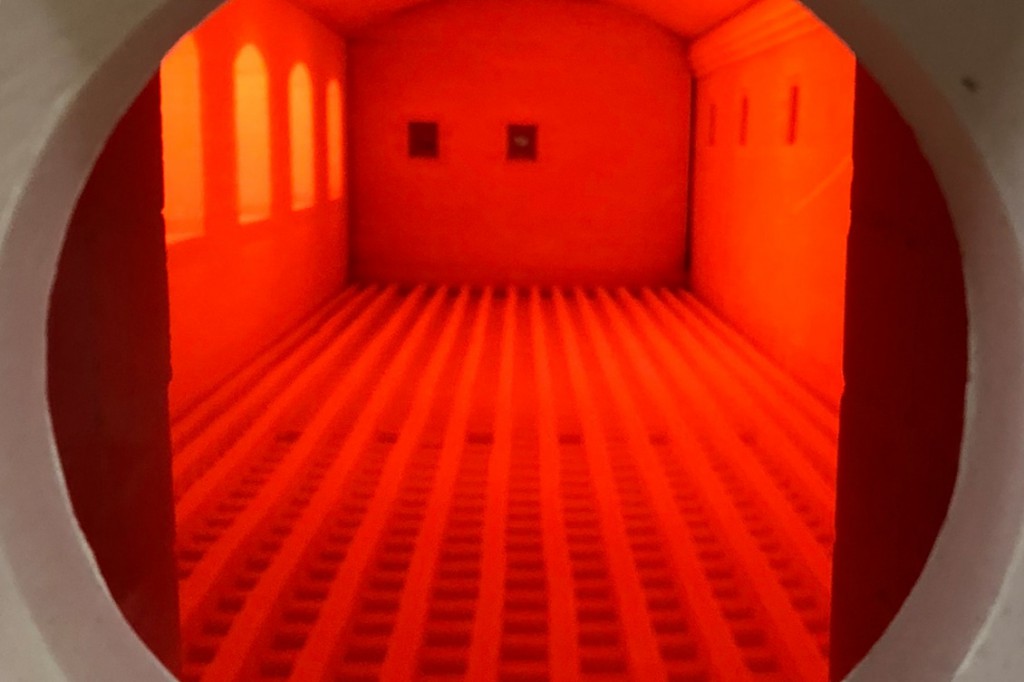

If glass furnace regenerators are experiencing flow restrictions and blockages due to the accumulation of sulfates, Hotwork can provide a service that helps to remove the blockage and lets the furnace “breathe” again. Removing the blockage can improve energy efficiency and productivity. Hotwork performs this service by installing a portable burner in the flue below the rider arch elevating the temperature of the lower checker pack. This process liquefies the sulfates and causes them to flow to the bottom of the regenerator. The client must be prepared for the flow of liquid sulfates and remove the solidified material at the conclusion of the process. The photos below show the before, during and after conditions during this process.

For more information on our Checker Packs services, please download our: